Metal 3D Printing: Printing in Metal with Precision and Durability

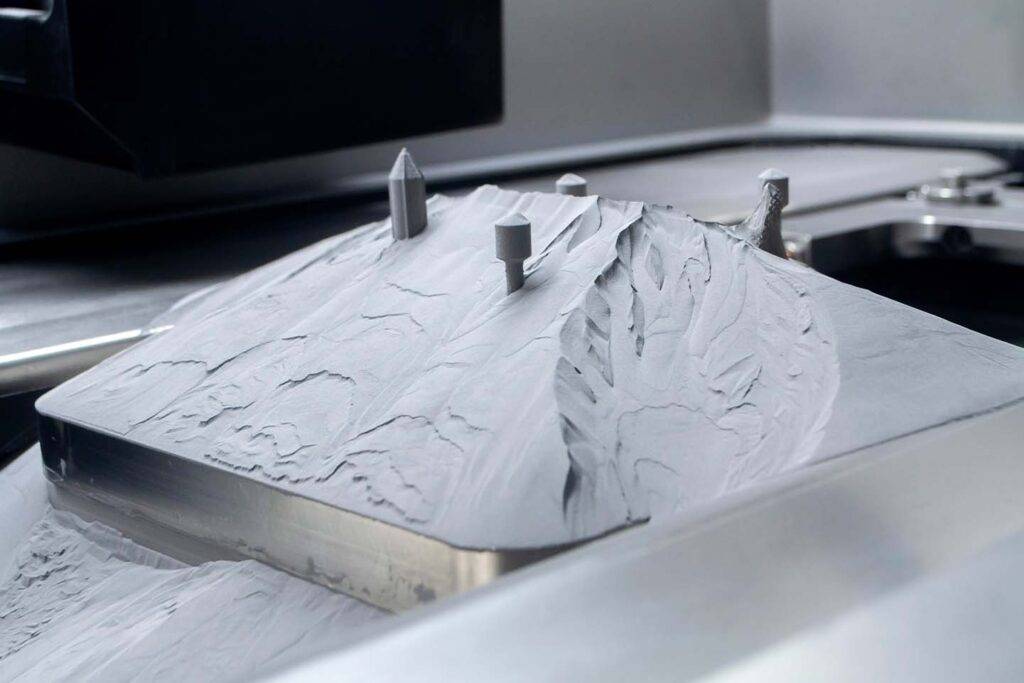

The metal 3D printing is the most advanced form of Additive Manufacturing for the production of parts from real metals. Unlike traditional methods (CNC machining, casting), here the object is created layer by layer from metal powder or filament, using a laser or binder.

It is the ideal solution for applications requiring high mechanical strength, geometric freedom, weight savings and the ability to produce in low quantities without tooling costs.

Advantages of Metal 3D Printing

Real metal parts, suitable for use.

High accuracy and detail, ideal for complex geometries.

Construction without molds or machining.

Weight saving with optimal design (topology optimization).

Less waste in relation to material removal machining.

Fast production prototypes or final parts.

Personalization with zero adjustment costs.

Metal 3D Printing Technologies

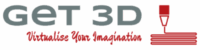

SLM (Selective Laser Melting)

The most widespread technology for 100% metal objects. A high-power laser is used to melt metal powder layer by layer.

DMLS (Direct Metal Laser Sintering)

Similar to SLM, except the powder is welded instead of completely melted. Suitable for non-ferrous alloys.

Binder Jetting

Instead of a laser, a liquid binder is used to bind the metal powder together. This is followed by heat treatment (sintering). Lower cost, larger quantities.

Metal 3D Printing Materials

- Stainless steel (316L, 17-4PH) – Corrosion resistance & mechanical stability

- Aluminum (AlSi10Mg) – Ideal for lightweight and durable components

- Titanium (Ti6Al4V) – High strength/weight ratio, biocompatible

- Cobalt-Chromium Alloys (CoCr) – For high temperature applications

- Inconel (718) – High resistance to temperature and oxidation

How do you start?

For printing on metal you need a 3D file in format .STL or .STEPIf you already have your design, you can send it for personalized offer.

Contact us and upload your file for immediate evaluation. s

and upload your file for immediate evaluation....

If you don't have a model ready to print, our team can also take care of it and design (3D design) from scratch, based on technical drawings, photographs or functional requirements.

When is Metal Printing the Best Choice?

- The CNC machining is expensive or impossible due to geometry

- It is required rapid production without tooling.

- There is a need for industrial strength with low weight.

- You want to create metal prototypes without mold costs.

- You need original fully functional parts.

Not sure which technology to choose? We are here for technical guidance.

Frequently Asked Questions – FAQ

How much does metal 3D printing cost?

The cost depends on the size, material and geometry of the object. For an accurate quote, send us your model via contact form.

Are the metal objects fully functional?

Yes. It's about 100% metal components, suitable for use in industrial applications.

What is the manufacturing accuracy?

The accuracy is approx ±0.1 mm, depending on the size and technology chosen.

Is there post-processing?

Of course. We offer sandblasting, CNC finishing, polishing, heat treatment and surface coatings.