Reverse Engineering in Greece: From Tubular Race Car Frame to Full CAD

There are cases where reverse engineering is not just useful, but the only way to move a project forward. When there are no blueprints, when the geometry is complex, and when accuracy is critical, digitally capturing a physical object becomes the only way.

A typical, real-world scenario we have implemented at Get3D involves 3D scanning and converting to CAD a tubular racing car chassis. The chassis existed only as a physical structure, without technical drawings or digital files, but it needed to be accurately captured in order to be used in further design, improvements and production.

This particular project clearly highlights the power of reverse engineering when applied correctly.

What is Reverse Engineering and how was it applied to the chassis?

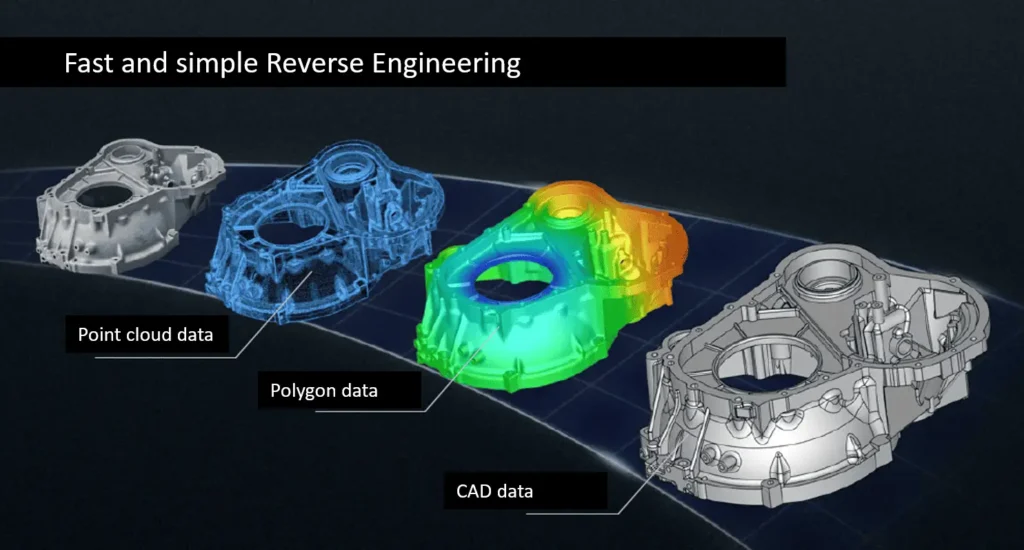

Reverse engineering, in this case, started directly from the physical object. Through professional 3D scanning, the entire tubular frame was digitally captured, creating an accurate point cloud.

The point cloud contained all the critical information: pipe routes, angles, distances and connection points. From there, surface and solid modeling followed, transforming the physical structure into a fully controllable digital model.

Digitizing objects through reverse engineering allows for exactly that: the transition from handmade construction to mechanical precision.

The real problem

The tubular chassis was hand-built, with different angles, curves and welds, making it impossible to reliably model it using conventional measurements. There was no CAD, no reference drawing, and the geometry had to be modeled with millimetre precision.

The goal was not just to visually represent the frame, but to create a complete, parametric CAD file that:

- will form the basis for future production or development

- will be used for geometry study

- will accept modifications and reinforcements

The 3 Stages of the Process at Get3D (Case Study)

1. 3D Scanning of the tubular frame

The chassis was scanned with a professional, high-precision 3D scanner to accurately capture all of its geometry. The process allowed for the capture of even complex connection and welding points.

Get3D's 3D scanning services are designed for demanding, large-scale objects, where data accuracy and consistency are critical.

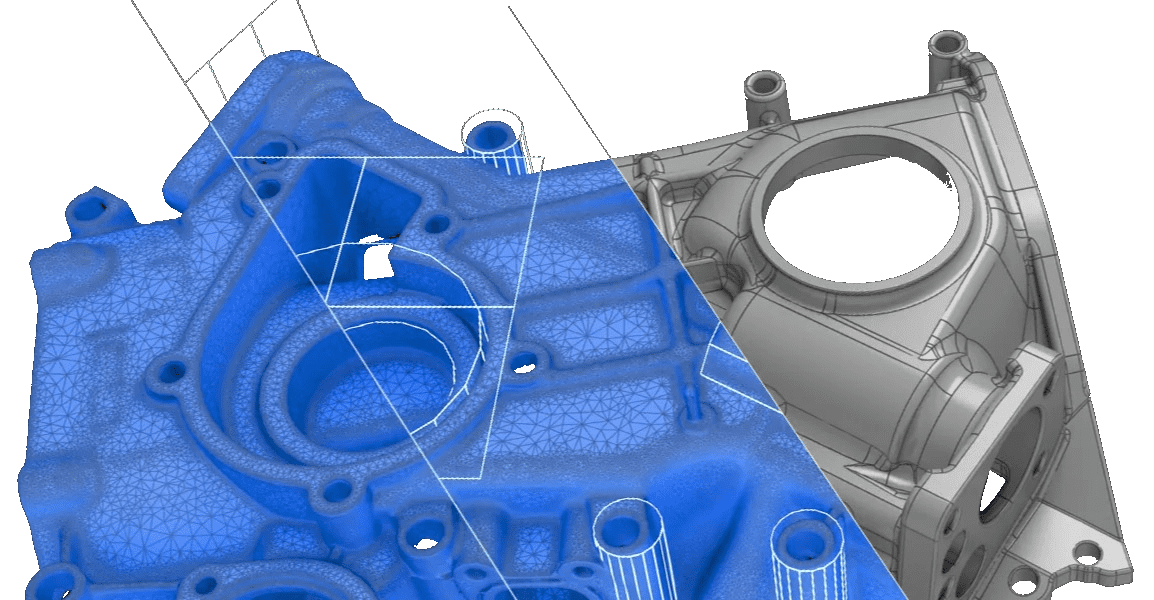

2. CAD design from scan

At this stage, the CAD design was carried out from a scan. The point cloud was used as a reference to create axes, pipes and nodes, with correct geometric relationships.

The result was a fully parametric CAD model, in which each tube could be modified, reinforced or redesigned. The file was delivered in STEP format, ready for analysis, modification & production.

3. Use of CAD in Product Development & Production

With the digital model of the chassis complete, the project moved into the product development phase. CAD was used for stiffness studies, geometry adjustments, and component design.

The existence of reliable CAD paved the way for repeatability, future production, and documented improvements, something impossible without reverse engineering.

Where is this procedure applied?

This particular racing chassis example shows how critical reverse engineering is in applications where precision and safety are crucial.

The same procedure also applies to:

racing and special vehicles

industrial frames and structures

mechanical assemblies without available drawings

Development

At Get3D, reverse engineering is a key part of Manufacturing HubThe CAD resulting from the scan is not the end of the process, but the beginning.

It can lead to:

- 3D printed fixtures and prototypes

- CNC machining of individual parts

- integrated product development

All stages remain under unified control, with a clear picture of cost and time.

Stay tuned!

This article is part of a real reverse engineering project that is currently underway.

The 3D scanning process and the conversion of the tubular chassis into a full CAD file have already been completed and form the basis for the next stages of the project.

We will soon add new technical details regarding the evolution of the design, the improvements made and the transition from the digital model to the final implementation.

Stay tuned for the completion of the project and more real-world examples of reverse engineering from Get3D.