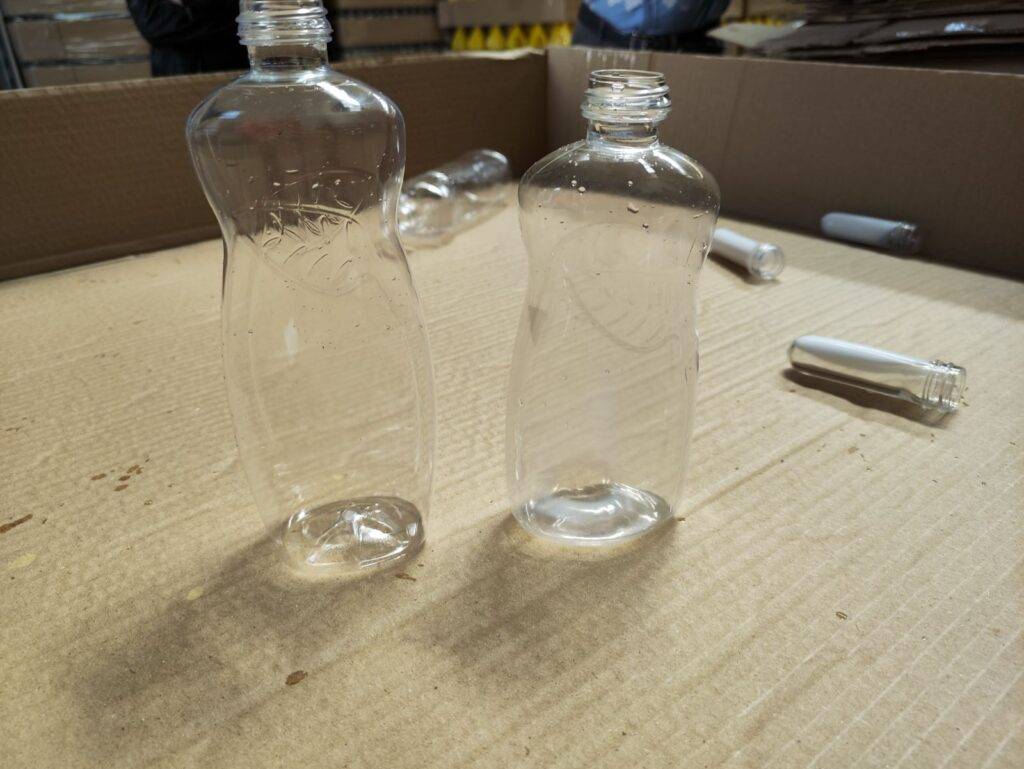

A totally challenging in many perspectives project was handled from our team during last weeks. On demand to one of our partners, who is manufacturing PET bottles using “blowing” techniques, there was a request to create a shorter bottle.

While the conventional method required the construction of a new mold with a delivery time of approximately 1-2 months and a cost that would reach €10,000.00, the order did not justify either the delivery times or the budget as the new bottles were a special order in a limited quantity (around 20,000 pcs).

Our designers studied carefully this challenging project and after some calculations we decided to move on this challenging project not only for us but also for the 3D printing technology itself

Using some of the most professional and high-quality 3D scanner our design team created a fully digital design of the original mold and the corresponding bottle, while using digital design software CAD, reverse engineering conducted on mold and bottle in order to create a fully parametrical design. The necessary changes and additions on the mold conducted without changing the operability of the already existing mold. All additions and new parts were 3D printed using FFF technology and the new upcomers, and highly promised Zaxe with materials that they were carefully chosen to operate under the working conditions of the machine, and unfortunately, we cannot announce.

The manufacture of 20.000 bottles was conducted by changing only one of the newly 3D printed parts four (4) times (an actual production rate of 5000 bottles/part). The total process of design and testing lasted about a week, while the total production was delivered after a total of ten (10) days!! The delivery time was minimized around 80% compared to conventional manufacturing technologies, while a similar reduction was conducted to the total production cost, which would be non-profitable following a conventional way.

In order to learn more and to take the advantages of the Additive Manufacturing (AM) technologies you can contact one of our experts here.