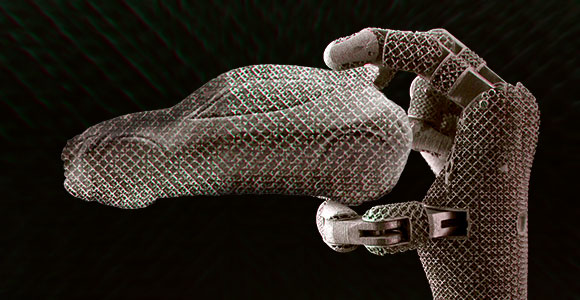

The industrial sector and especially the construction industry was the one that created 3D printing or as it is more officially referred to as additive manufacturing. Throughout the industry, 3D printing in recent years has evolved from one method of prototyping to another method of manufacturing.

We could not, therefore, as a company with great specialization in the industrial sector, not create a special department for the industrial sector & industrial 3D printing. Our special industrial department is able to help you every step of the way in this new manufacturing technology of 3d printing.

Our department employs engineers with the main subject of engineering and with specialization and experience in industrial construction and product development. Equipped with our specialized knowledge and our experience in industrial applications, we will help you to complete any project you ask for.

Industrial 3D printing applications

Reverse Engineering

Reverse engineering is used in a number of applications both from the need to transition older products to the new digital age, and as a first step before improving an existing product.

In our company we use a lot of equipment both for digital printing (3d scanning) as well as for the reverse engineering process itself (surface modeling software, but also CAD for solid modeling).

With high expertise in the design of products, components and other items related to industrial applications we are able to identify the important points of a reverse engineering process and you receive a digital design fully customizable for the needs of your own design department.

Mass Production

Our company has one of the largest "farms" of 3D printers, while at the same time it also has almost all available 3D printing technologies in Greece. In this way we are able to provide production services of a series of products according to the needs of the new era. The production of many products in the modern market requires very high customization and constant updates to always be relevant.s

Of course, one realizes that constant changes and high customization cause quite large costs in the production units as both the process of designing a new product and the programming of a traditional unit require hours and many materials and tests.

At this point, our company offers you the above without increasing production costs. This happens as by leveraging the solution of small flexible product producers you reduce the cost of creating tools (e.g. molds), labor costs (3d printers work 24/7 without supervision), storage costs (in many cases you don't even need to have small stock in the warehouse, everything is produced on demand), the cost of materials (the 3d printer uses only the necessary material) etc.

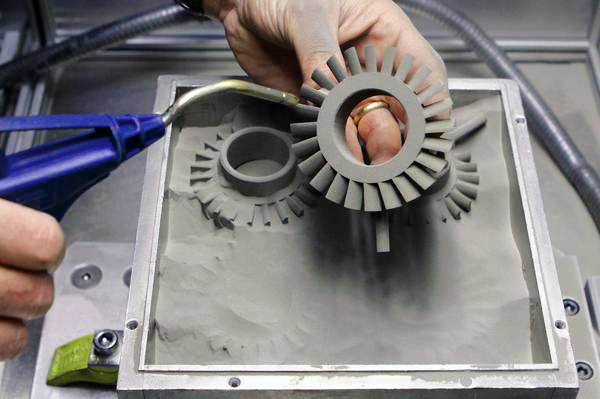

Rapid Prototyping

A large reduction in product development costs is achieved with the help of 3d printing in the prototyping process. By using prototypes one can quickly and economically identify possible design errors and correct them before it goes to the production stage.

The provision of services in the process of rapid prototyping, however, does not stop at the simple construction of a prototype. In our industrial department our people will help you choose the right materials (if they are not exactly the same as you will use in the actual product) so that you can get a fully functional prototype.

In this way you are not limited to a simple visual inspection of the prototype but you can delve deeper into the behavior of your product under real conditions. Of course, rapid prototyping services can also be used in cases where mold constructions are required for casting.

Economic and technical studies of equipment market

Many times the volume of work in an industry may require the acquisition of the same equipment so that there is not a large volume of outsourcing.

In the event that you decide that you would like to include additive manufacturing (Additive Manufacturing) in your production process, the industrial service department is here to help you achieve this without unnecessary costs and time.

Together we will examine the important points of your production process, your mode of operation, the requested materials and everything else related to the design and production of your products. This way we will be able to recommend the best solutions, adapted to your own data so that you can be fully productive from the first day.

Of course, our services don't stop there, as with special maintenance and support packages, you can be sure that your equipment will work smoothly every time you need it.

We are here to introduce you to our 3D space, without fear and without hidden spots, we have no qualms about passing on our knowledge and experience to our partners

If you do not know how 3d printing could join your industry then we are waiting to meet you. The future of construction is here and it is evolving, if you want to enter the new era and the possibilities that open up through prosthetic construction we are here to show you the way.