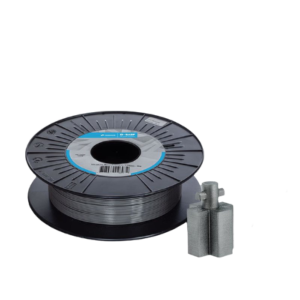

‘P-support 279’ is the world’s first breakaway support material specially developed for polypropylene, which allows the extrusion-based 3D printing of even more detailed and complex structures with bridging, overhangs and openings ‘P-support 279’ features high stiffness, low warpage and excellent adherence to the printed PP part and to the ‘P-surface 141’ 3D printing build surface. Therefore it is also ideal for producing rafts or support structures on printed PP. ‘P-support 279’ can be removed cleanly and easily from the printed part after heating to 100°C. A breakaway support material also has the particular advantage that no polymer waste containing solvents or water is produced. The breakaway thermoplastic support material ‘P-support 279’ is easily recyclable, making extrusion-based 3D printing with PPprint materials extremely sustainable.

Pre-treatment of ‘P-support’: ‘P-support 279’ requires no drying before 3D printing and can be used without any pre-treatment. Recommended printing parameters:

‘P-surface 141′ is required as 3D printing build surface

Extruder temp: 200-220° C

Printing bed surface temperature: 20 °C (50 – 70 °C during the first layer, 100 – 110 °C for non-destructive removal after completion)

How to remove the support material ‘P-support’ from the printed PP part:

After extrusion-based 3D printing, ‘P-support 279’ adheres extremely strongly to the printed PP part and the ‘P-surface 141’ 3D printing build surface.

Caution hot! Wear protective clothing and gloves to prevent burns. By heating ‘P-surface 141’ to 100 – 110 °C, the bottom ‘P-support 279’ layers become soft like chewing gum, so that the printed part and support structures can be removed non-destructively at this temperature. To remove ‘P-support 279’ printed further up in the part, the part with the adhering ‘P-support 279’ can be heated in an oven to 100°C or by immersion in boiling water. As soon as ‘P-support 279’ is completely heated up to 100°C, it can either be peeled off the 3D printed part immediately hot (protective clothing required) in its present chewing gum-like state or removed after cooling and solidification. The hot chewing gum-like state of ‘P-support 279’ also allows deforming and thus pulling out support structures which have been printed in openings or holes and have to be pulled or pressed through slightly smaller openings for removal. After the complete removal of the supporting material ‘P-support 279’ the PP component can be used.

Storage instructions: To ensure consistent print performance, ‘P-support 279’ should be used and consumed as soon as possible after opening (preferably within 15 months). It is recommended to store opened material at a temperature of 15 – 25°C and in a plastic bag to avoid dust contamination.