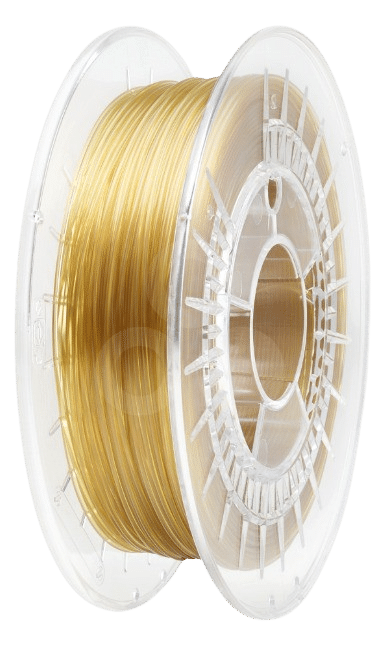

TECAFIL PEKK

Ensinger manufactures an unfilled PEKK filament – TECAFIL PEKK natural.

PEKK (Polyetherketoneketone) belongs to the group of PAEK filaments, making it one of the strongest natural filaments on the market. Ensinger’s PEKK filament is based on the 6000 series of ARKEMA Kepstan® resin. PEKK filament is becoming increasingly popular in additive manufacturing because it can be printed amorphously and is considered easier to process than PEEK. PEKK filament is often used for the replacement of metal components when optimisations are required in terms of light weight while maintaining strength.

The characteristics of PEKK plastics, such as excellent flame resistance and low smoke emission, allow them to be used in important industrial applications in aerospace and transportation. Good electrical insulation properties result in frequent use of PEKK filaments in the electronics industry. Many applications in the chemical, medical or bioprocess industries are also made from PEKK, as it shows good chemical resistance against acids, alcohols or ethers.

Why should you print our PEKK filament?

Some semi-crystalline or amorphous materials have problems with diffusion between layers or trans-layer crystallisation. Our PEKK filament is optimised for 3D printing due to its polymer structure and – especially the 6000 series – in terms of a slower crystallisation rate and high flow rate. This results in improved layer adhesion of your printed applications.

Using the structure of a copolymer, it is possible to precisely control the melting point and crystallisation rate when printing PEKK filament.

Printed PEKK components can be operated continuously at temperatures from 250 °C to 260 °C, with short-time exposure up to 300 °C. As PEKK is a high performance material, it can only be used on an industrial printer that complies with the recommended process parameters. The printing and part properties can be influenced by the printing parameters and post-processing. It is easier to print PEKK in an amorphous state and post-treat it to increase crystallinity and material characteristics.

Kepstan® is a registered trademark of Arkema S.A.

FACTS

PEKK (Polyetherketoneketone)

amber

1.27 g/cm3 (*2)

MAIN FEATURES

- inherent flame retardant

- good dimensional stability

- high heat deflection temperature

- high thermal and mechanical capacity

TARGET INDUSTRIES

electronics

automotive industry

chemical technology

mechanical engineering

aircraft and aerospace technology