3D Printing Services -

FDM, SLA, SLS & Metal

Our Technologies

Get3D is a pioneer in the field of 3D printing services, offering leading technologies such as: FDM, SLA, SLS and Metal Printing. The company is aimed at professionals, designers, engineers and businesses who need reliable prototypes, functional components and high-quality industrial solutions!

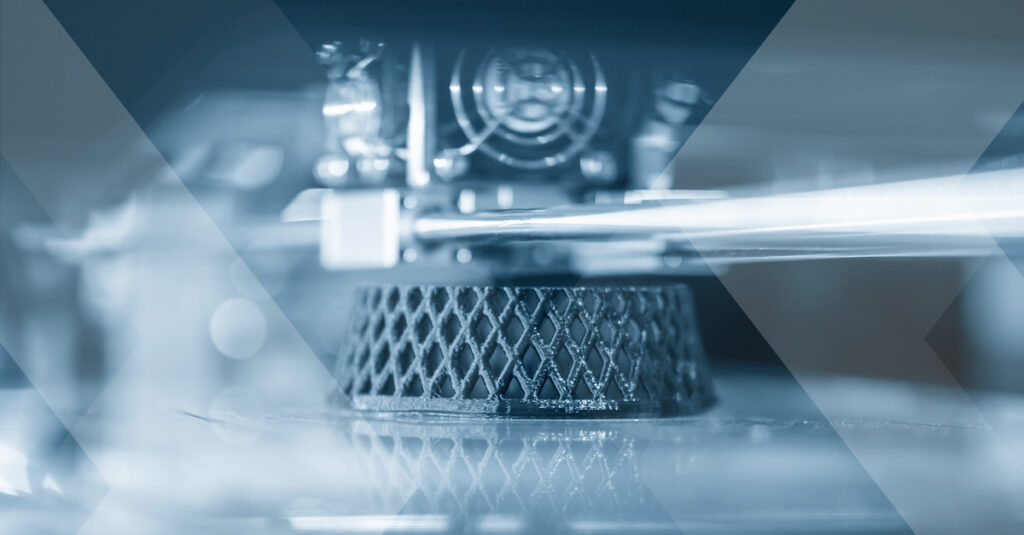

FDM 3D Printing(Fused Deposition Modeling) printing

The most common 3D printing method

- Economic production

- Durable components and models

- Functional prototypes

- Materials: PLA, ABS, PETG, TPU etc.

READ MORE

SLA printing (Stereolithography)

It uses liquid resin and laser to print details with extreme precision. It is suitable for:

- High precision molds and applications

- Medical/dental models

- Miniatures and demonstration prototypes

READ MORE

SLS printing (Selective Laser Sintering)

Prints with nylon powder without supports, ideal for:

- Small series production

- Industrial components

- High-strength mechanical parts

READ MORE

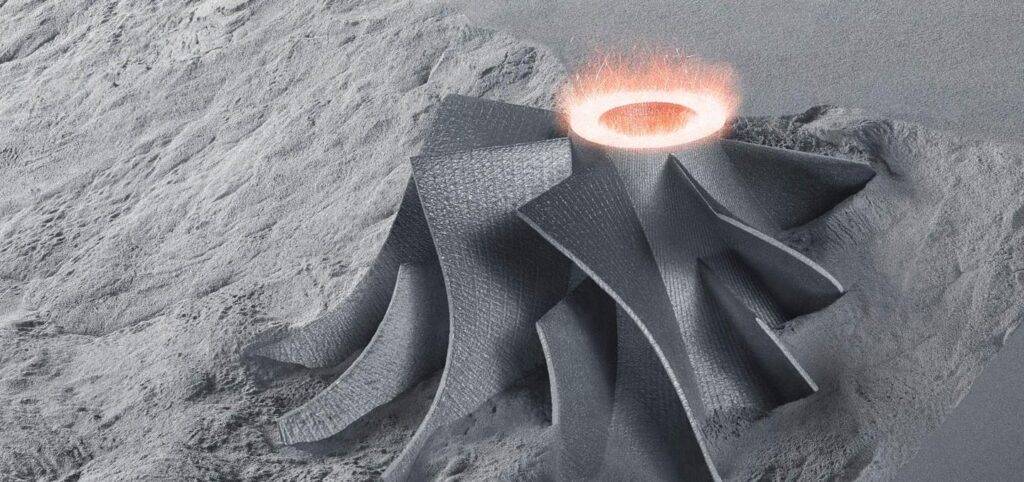

Metal 3D Print

Technology based on metal powders and lasers:

- Ideal for aerospace and mechanical applications

- Manufacturing of stainless steel, aluminum and titanium components

READ MORE

Online costing

Do you have a file?Upload your file, learn about the materials and appropriate technology and receive a comprehensive offer from our experienced team.

"If you don't have a file, we can create it for you via 3D Design»

Why Choose Get3D:

10 Years of Experience

- All leading technologies Τρισδιάστατης εκτύπωσης in one place

- Fast delivery (2–5 business days for the vast majority of jobs)

- Free cost estimate based on file (.STL / .STEP)

- Nationwide Mission with courier companies.

- CAD/CAM technical support and tailor-made solutions

- Quality guarantee in the final result

At Get3D, we pay special attention to the quality of each printed piece. We use only the best materials and choose the appropriate technology according to the customer's needs, ensuring durability, precision and aesthetics in the final product. Continuous monitoring and quality control at every stage of production ensure that we deliver results that exceed expectations.

3D Design

In addition to printing, Get3D offers services 3D designing and file optimization, so that the model is fully compatible with the respective technology and meets the requirements of your application. From simple modifications to complex projects, our team is by your side to transform your idea into a functional product.

Standards

You set the specifications, we take care of the rest.

Results at your demands

Our team will be in touch with you at every step of your project.

Warranty

We are confident that we will deliver exactly what we promised you, so we guarantee our work.

Who benefits from our services?

- Engineers & Designers: for test fitting, testing and pre-production prototypes

- Businesses & Industries: for functional parts and small productions

- Doctors & Dentists: for precise medical/dental models

- Artists & Creators: for successful works of art and unique objects

- Educational Institutions: for educational models, prototyping and hands-on projects

Frequently Asked Questions (FAQ)

What is SLA 3D printing?

A technology that uses UV lasers to solidify resin, offering excellent detail and a smooth surface.

What are the uses of SLS technology?

It is used in mechanical components, functional prototypes and small production runs.

Which printing method is best for metal objects?

Metal printing via SLM or DMLS is most suitable for high strength and precise dimensions.

How can I calculate the cost of printing?

Do you offer shipping throughout Greece?

Yes, we ship with reliable carriers to every region of the country.

How much does 3D printing cost?

It depends on size, material, and complexity—get a free estimate.

Start your next 3D project today!

Send us your file for free estimate or contact with our team to find the best solution for you.