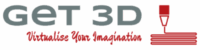

BASF Ultrafuse 316L (1.4404) is an innovative polymer-containing metal yarn for the production of all-metal parts using the simplest 3D printing (FFF) process. Benefit from years of experience with Metal Powder Casting (MIM) technologies and a proven debinding and sintering process (Catamold®).

The thread has a metal content of over 80%. The even distribution of the metal within the bonding matrix reduces the risk of errors and increases the success rate. Due to the immobilization of the metal particles in the bonding matrix, the risk of handling fine metal dust is drastically reduced compared to Selective Laser Melting (SLM), Direct Metal Laser Sintering (DMLS), Direct Metal Deposition (DMD) and Binder Jetting.

The Ultrafuse 316L is compatible with both Bowden extruders and direct drive extruders.

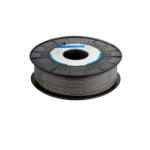

The printed pieces must be sent to BASF for the conversion process from the green part to the final sintered metal object.

Required purchase of ticket for the debinding & Sintering process

Comes in a 3kg package

Contact us for more details