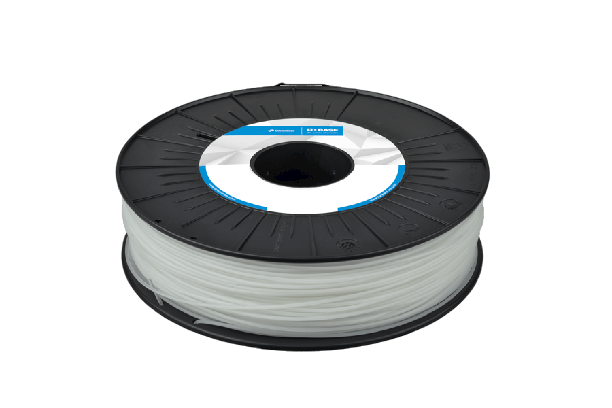

BASF Ultrafuse PA Natural

Ultrafuse PA is suitable for a wide range of applications working within a larger temperature range than normal PA filament. BASF‘s Ultramid® grades are molding compounds on the basis of PA6, PA66 and various co-polyamides such as PA6/66.

Ultramid® is noted for its high mechanical strength, stiffness and thermal stability.

In addition, Ultramid® offers good toughness at low temperatures. Owing to its excellent properties, this material has become indispensable in almost all sectors of engineering for a wide range of different components and machine elements, as a high-grade electrical insulation material and for many special applications.

Ultrafuse PA is the translation of BASF´s Ultramid® to 3D printing space.

With Ultrafuse PA, it is possible to print semi-flexible thin parts, however it is very stiff in higher thicknesses. It has a lower melting temperature than PA6 and PA66 hence it can be printed in a lower temperature as well as it has better impact strength against PA6 and PA66 which opens up a new application field to the end-users. Depending on specific requirements, the formulation can be optimized further, and special filaments can be created.

Advantages of Ultrafuse PA

• Good fatigue resistance

• Low melting point makes it printable for many FFF printers

• Good wear resistance/lubricity

You can see the TDS here.

Don't hesitate to contact us for any information.