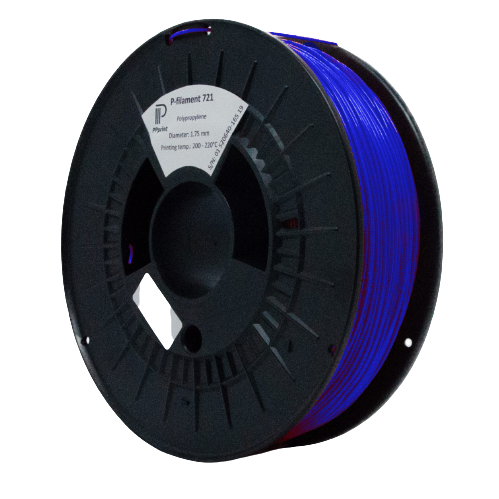

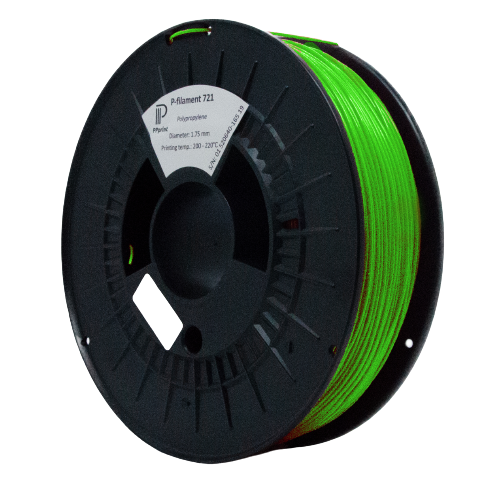

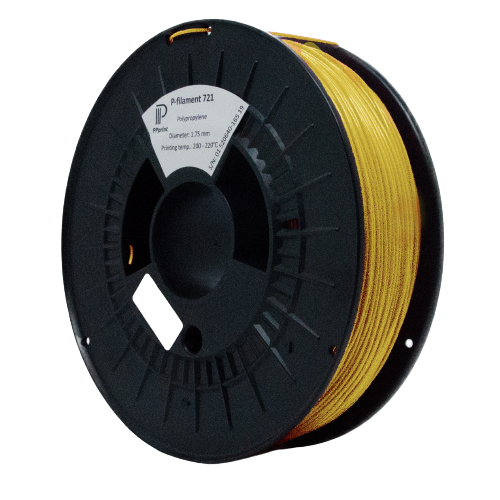

P-Filament 721 of PPprint manufacturer consists the absolutely simplified solution for 3D printing PP in 3D printers without heating chambers. Its special formula for reducing shrinkage which creates warping effects, in combination with the special manufactured and necessary build platform creates perfect adhesion for the first layers and high-quality fusion between next layers. 3D printed parts from P-Filament 721 are presenting great mechanical behavior, extreme chemical resistance, rather non-effected behavior under thermal stress, while a very low friction coefficient also exists. Its low density makes it the most appropriate material for light-structure, without compromising mechanical efficiency. PP's applications in the world of plastics are already known and all restriction for applications in 3D printing are eliminated with the absolute solution of PPprint.

Preparation of PP-filaments ‘P-filament 721‘:

‘P-filament 721’ does not need to be dried before 3D printing and can be used without pre-treatment.

Storage instructions:

To ensure constant print performance, ‘P-filament’ should be used as soon as possible after opening (preferably within 15 months). It is recommended to store opened material at a temperature of 15 – 25°C and in a plastic bag to avoid dust contamination.

P-filament 721 natural is biological certified according to DIN EN ISO 10993-5 and is therefore ideal for 3D printing components that come in contact with the skin.

* It's required to use “P-Surface 141”

Package of 600g