The requirements of our customers are decisive for us as a plastics manufacturer in all developments. Thus, also in the extrusion of filaments, the goal is to select the most suitable material for your printer and your specific applications and requirements. In doing so, we are not limited to one raw material or supplier. That’s why, in addition to our PEEK filament based on Victrex® PEEK 450, we offer a PEEK filament based on VESTAKEEP®.

The basic material properties correspond to those of our Victrex PEEK filament (for more details, see TECAFIL PEEK VX natural). Nevertheless, there are also differences in some material properties. Due to the melt flow rate (MVR) around 15.5 g / 10 min (380 °C / 5 kg) TECAFIL PEEK EV natural exhibits a lower viscosity than TECAFIL PEEK VX (10 g / 10 min). Furthermore, both PEEK filaments show different crystallization behavior. TECAFIL PEEK EV natural is characterised by a significantly later crystallization time.

By using the appropriate parameters, better layer adhesion in the XZ direction and better mechanical properties for high loads can thus be achieved, even under simpler printing conditions.

Depending on your printer, the printing parameters and the size of the part, one or the other PEEK filament may give a better result.

The base polymer of this filament meets the requirements for food contact according to (EC) No 1935/2004, (EU) No 10/2011, (EC) No 2023/2006 and FDA. Migration tests according to EU 10/2011 were successfully performed on similar extruded specimens. Legally binding documents must be requested separately.

VESTAKEEP® is a registered trademark of Evonik Industries AG.

The basic material properties correspond to those of our Victrex PEEK filament (for more details, see TECAFIL PEEK VX natural). Nevertheless, there are also differences in some material properties. Due to the melt flow rate (MVR) around 15.5 g / 10 min (380 °C / 5 kg) TECAFIL PEEK EV natural exhibits a lower viscosity than TECAFIL PEEK VX (10 g / 10 min). Furthermore, both PEEK filaments show different crystallization behavior. TECAFIL PEEK EV natural is characterised by a significantly later crystallization time.

By using the appropriate parameters, better layer adhesion in the XZ direction and better mechanical properties for high loads can thus be achieved, even under simpler printing conditions.

Depending on your printer, the printing parameters and the size of the part, one or the other PEEK filament may give a better result.

The base polymer of this filament meets the requirements for food contact according to (EC) No 1935/2004, (EU) No 10/2011, (EC) No 2023/2006 and FDA. Migration tests according to EU 10/2011 were successfully performed on similar extruded specimens. Legally binding documents must be requested separately.

VESTAKEEP® is a registered trademark of Evonik Industries AG.

COMPLIANCES

FACTS

Chemical designation

PEEK (Polyetheretherketone)

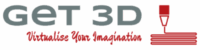

Colour

beige

Density

1.3 g/cm3 (*2)

MAIN FEATURES

- inherent flame retardant

- very good chemical resistance

- good slide and wear properties

- good heat deflection temperature

- resistance against high energy radiation

- hydrolysis and superheated steam resistant

TARGET INDUSTRIES

electronics

food technology

automotive industry

chemical technology

mechanical engineering

aircraft and aerospace technology