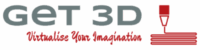

TECAFIL PEI 9085

The search for an ULTEMTM 3D printing filament usually leads to two types available on the market, ULTEMTM 1010 (or 1000) and 9085. TECAFIL PEI 9085 natural is based on the Sabic ULTEMTM 9085 material and is an unfilled PEI (polyetherimide) filament.

ULTEMTM 9085 filament is an amorphous high performance polymer with beneficial properties for numerous applications. This ULTEMTM filament can be used to print parts that can withstand high temperatures and high stresses.

TECAFIL PEI 9085 natural is inherently flame retardant and causes low smoke emission (meets UL94-V0). The combination of these FST (Flame, Smoke and Toxicity) safety standards with outstanding mechanical properties in terms of stiffness, high dimensional stability and high creep resistance over a wide temperature range makes PEI a frequently used material in the transport and aerospace sectors as well as in the automotive industry.

Due to its good electrical insulation properties, ULTEMTM filaments are also very widely used in the electronics and semiconductor industries. Thanks to its good radiation and chemical resistance, PEI 3D printing is also in demand for medical applications.

These characteristics make PEI filaments a suitable material for functional parts, prototypes and production tools. Applications printed with ULTEMTM filament have a continuous temperature resistance of up to 170 °C.

ULTEMTM is a registered trademark of the Saudi Basic Industries Corporation (SABIC).

ULTEMTM 9085 filament is an amorphous high performance polymer with beneficial properties for numerous applications. This ULTEMTM filament can be used to print parts that can withstand high temperatures and high stresses.

TECAFIL PEI 9085 natural is inherently flame retardant and causes low smoke emission (meets UL94-V0). The combination of these FST (Flame, Smoke and Toxicity) safety standards with outstanding mechanical properties in terms of stiffness, high dimensional stability and high creep resistance over a wide temperature range makes PEI a frequently used material in the transport and aerospace sectors as well as in the automotive industry.

Due to its good electrical insulation properties, ULTEMTM filaments are also very widely used in the electronics and semiconductor industries. Thanks to its good radiation and chemical resistance, PEI 3D printing is also in demand for medical applications.

These characteristics make PEI filaments a suitable material for functional parts, prototypes and production tools. Applications printed with ULTEMTM filament have a continuous temperature resistance of up to 170 °C.

ULTEMTM is a registered trademark of the Saudi Basic Industries Corporation (SABIC).

COMPLIANCES

FACTS

Chemical designation

PEI (Polyetherimide)

Colour

beige

Density

1.34 g/cm3 (*2)

MAIN FEATURES

- inherent flame retardant

- high dimensional stability

- high thermal and mechanical capacity

- resistance against high energy radiation

TARGET INDUSTRIES

electronics

automotive industry

mechanical engineering

aircraft and aerospace interiors